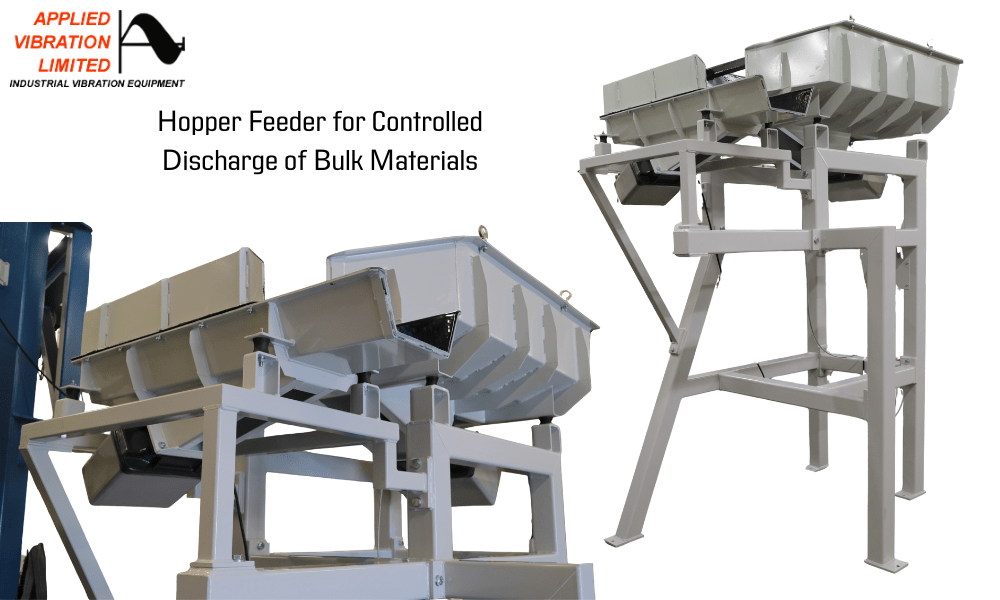

The AV Hopper Feeder is a long established solution for the bulk storage and handling of parts, and was originally designed and developed in conjunction with packaging machine manufacturers to allow a stillage of parts to be discharged at a controlled rate.

From a hopper feeder, the material discharges in a way that streams the product from the bulk pile created by tipping in a full stillage. This thins the product out in depth and even providing a small degree of untangling,

The discharge from the hopper feeder is collected in a tray feeding across the discharge to centralise the product and deliver it to the part counting, part weighing or part orientation system.

Although originally designed for fasteners and small parts, the equipment has also been used in applications in the food industry for frozen foods, the granulation industry with rubber and plastics and even for some powder filling applications.

We were recently called upon to provide a special unit to feed an existing packing line. In this line, the infeed height was determined by an existing tipper unit and the discharge height was restricted by the guarding height on a new packaging machine.

Applied Vibration Limited were asked to design a solution that would load and discharge in the conventional manner but could be accommodated within the dimensions that were being dictated by both the existing tipper and the new packaging line.

We designed a special profile for the hopper that allowed material to both be filled and discharge from what was a comparatively shallow unit in a way that still made it controllable for delivery to the packaging machine.

Whilst we have a comprehensive range of standard equipment we fully appreciate that re-design and adaptations can help bring together working solutions for our customers.